We offer 3, 4, and 5-axis milling. We are currently outfitted with HAAS vertical mills, a TR-160 Trunnion table to allow for 5-axis machining as well as a new HAAS UMC 750SS for increased 5-axis capabilities .

We offer Multi-tasking Turning capabilities. With the live tooling capability of the MAZAK 250MY, we are able to machine in both the C and Y-axis. This versatility allows us to eliminate the need in most instances for secondary operations on the mill.

With the FANUC ROBOCUT C600IA Wire EDM, we are capable of making more intricate parts with higher precision and tighter tolerances. We also have the capability to run parts overnight unattended, with the use of custom fixtures.

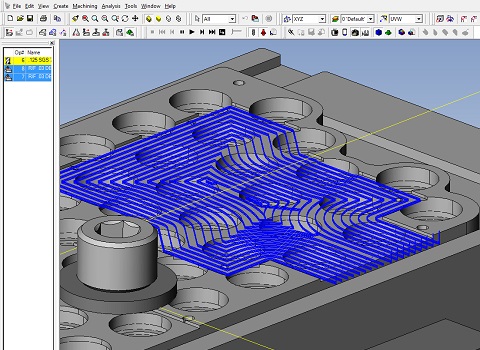

We utilize EspritCAM software for machine code programming. We also have implemented the use of Solidworks as well as Solidworks Inspection. This allows us to work with many different file types through Solidworks, as well as balloon drawings and create inspection sheets with Solidworks Inspection to comply with our ISO 9001 Quality System. This reduces down time to be minimal to none to ensure quality and efficiency. We utilize E2 Shoptech Software for estimating, quoting, scheduling, job routing, material tracking, shipping, and receiving.

We are ISO 9001 certified under the SRI Quality Systems Registrar. Here is a link to our certificate. We utilize an ERP system, travelers, inspection reports, and balloon drawings. We conduct receiving, first piece, in-process, and final inspections (plus first article as required). First piece inspection is a full 100% characteristic check at each setup with two separate operators/inspectors. Sample sizes are coordinated per the part tolerance specifications, characteristic classifications and process complexity.